In today’s global market, supply chain dynamics and trade policies are evolving at breakneck speed. Recent tariff adjustments—a 90-day pause for most countries at just 10%, while imports from China still face steep tariffs of up to 125%—have upended traditional manufacturing paradigms. Many companies, especially those selling to the U.S., are feeling the pressure to diversify their supply chains and rethink their product roadmaps.

At World Sourcing Ltd., we’ve been closely monitoring these changes and working with our clients to develop flexible, cost-effective OEM solutions. Instead of relying solely on a single direct factory—often a risky, reactive approach—our strategy is to build robust, diversified supply chains that adapt to market shifts while driving innovation and quality.

The New Trade Reality: Flexibility Over Dependency

Recent trade policies serve as a wake-up call: it’s not just about finding the largest factory, but about managing a network that works for your brand. We’ve spoken with numerous clients who are exploring options like local bonded warehouses for short-term cash flow relief, tariff engineering, and comprehensive supply chain mapping. The objective is clear: reduce risk by “putting your eggs in many baskets.”

Key strategic insights include:

Tariff Engineering: Smartly adjusting product design or materials to legally reduce import duties—helping you stay compliant while cutting costs.

Implementing transparent tariff surcharges helps maintain cost clarity throughout the supply chain.

This approach enables you to price products fairly while remaining competitive.

Diversification of Markets and Suppliers:

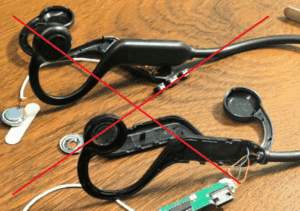

Do not rely on a single factory or market.

Our flexible OEM model leverages multiple manufacturing partners, ensuring that if one link in the chain is weak, your overall product supply remains strong.

Redesigning Your Product Roadmap:

In response to shifting trade policies, re-evaluating product features and supply chain designs is critical.

Our engineering team works with you to tailor designs that combine innovation with cost efficiency, ensuring your products meet stringent quality and performance standards.

Local Bonded Warehouses and Supply Chain Mapping:

Quick, strategic responses like setting up local bonded warehouses can ease short-term cash flow challenges.

Comprehensive supply chain mapping lets you identify and manage risks across international borders.

No Dependency—Full Control:

Rather than being stuck with a factory that might be caught in a trade impasse, work with a strategic OEM partner that designs, customizes, and manages your supply chain for you.

Industry Insights: Trends Driving Strategic Planning

Even if your business is not focused on the U.S. market, these trends are universal. Recent data shows that Asia, with its higher exposure to tariffs and a greater proportion of exports to the U.S., is at the frontline of these changes. Key trends include:

Regional Variations in Tariff Exposure:

Southeast Asia experiences around 34% tariff rates and 11% export reliance to the U.S.

- East Asia, by contrast, has around 27% tariffs with 9% of exports to the U.S.

- Negotiation Pressures:

With 75 countries in negotiations over tariffs, the most exposed markets must offer concessions or incentives to minimize risk.

Note: There are products that simply cannot be produced locally in places like Sri Lanka or the USA in the near future. This highlights the importance of understanding the risks associated with each supply chain zone and designing manufacturing strategies accordingly. For instance, What if Vietnam imposes a 30%-50% import tariff on raw materials from China, and some critical materials are only available from suppliers in “red zones.” It’s crucial to assess these risks strategically—recognizing that not every factory operates globally—so that you can build a resilient, cost-effective supply chain that meets your production need.

Part 2: Industry Trends and the Future of Product Innovation

Beyond trade policy, keeping abreast of market trends is critical. The latest insights reveal:

Increased Demand for Smart & Sustainable Products:

Industries such as smart home devices, electric mobility, and health tech are evolving, driven by consumer demand for efficiency, sustainability, and user-friendly designs.Accelerating Adoption of AI-Integrated Devices:

The rise in AI-enabled technology offers a transformative edge across product categories. This trend is not just shaping consumer expectations but also re-defining supply chain strategies.Resilience in Manufacturing and Distribution:

Companies that adapt swiftly to trade disruptions and diversify their manufacturing bases are reaping long-term rewards. Efficient supply chain control and proactive planning are now more valuable than ever.

Why Partner with World Sourcing Ltd.?

At World Sourcing Ltd., we blend deep engineering expertise with strategic OEM management to give you the advantage that top national brands enjoy. Our tailored solutions—from rapid private labeling to fully customized product development—are designed to reduce risk, improve product quality, and drive innovation in your supply chain.

Ready to future-proof your supply chain and launch innovative products?

Contact us today to design an OEM strategy that gives you full control and market agility.

“I’d love to exchange ideas and learn more about your thoughts on your new supply chain strategy.”

Director/Jerry Kung.