Case Studies

Selected examples of OEM and ODM product development projects delivered by World Sourcing Ltd. These case studies highlight our engineering approach, manufacturing execution, and ability to support products from early development through mass production.

Turning into Manufacturable Products

World Sourcing work with brands, startups, and retailers to transform product ideas and existing designs into scalable, manufacturable products. We emphasize engineering, tooling, and seamless production execution to bring your vision to life.

Engineering-Led OEM Projects Across Categories

Each case study focuses on engineering challenges, development decisions, and manufacturing outcomes. Client names may be anonymized where required, while technical scope and execution details are preserved.

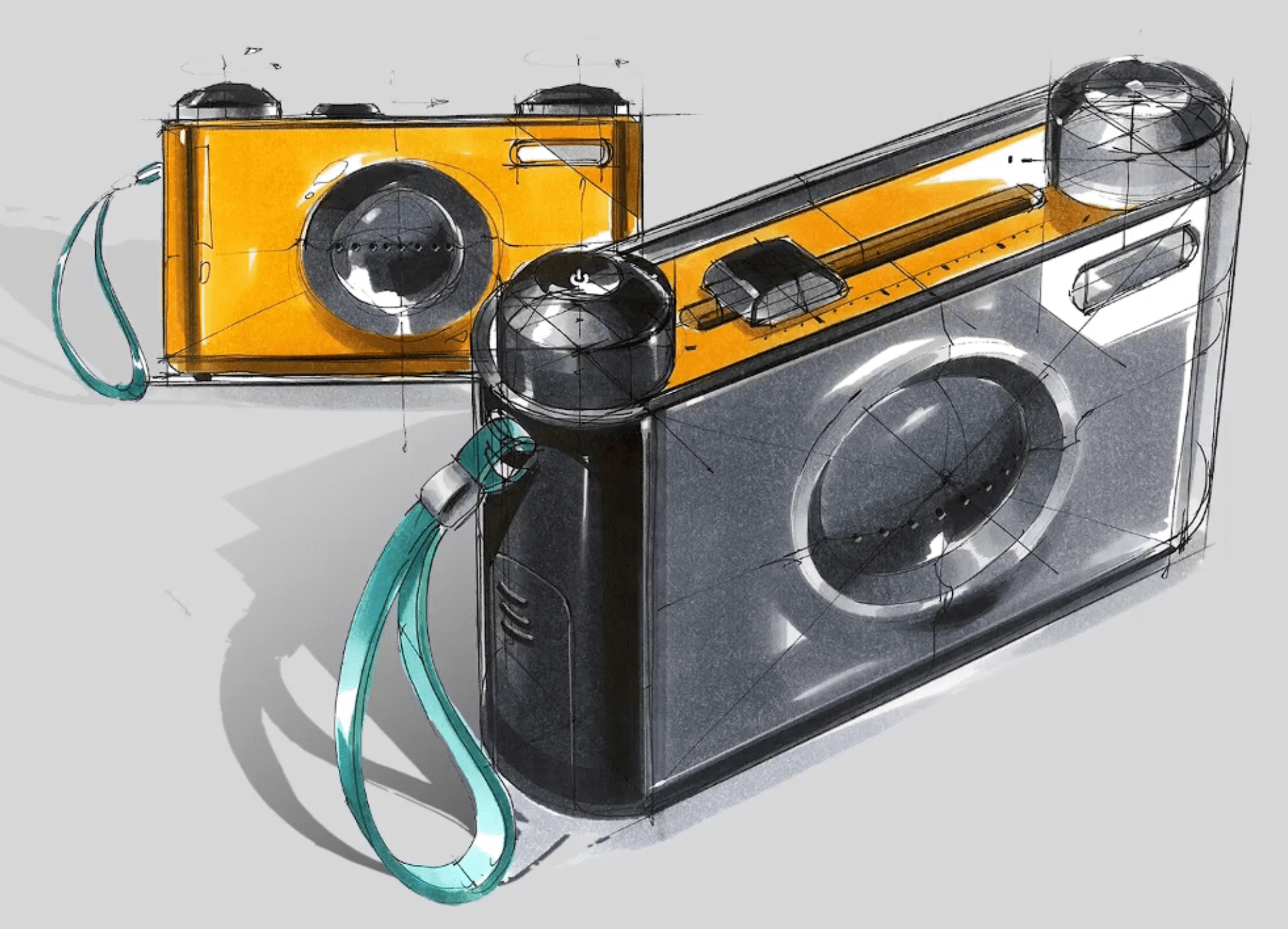

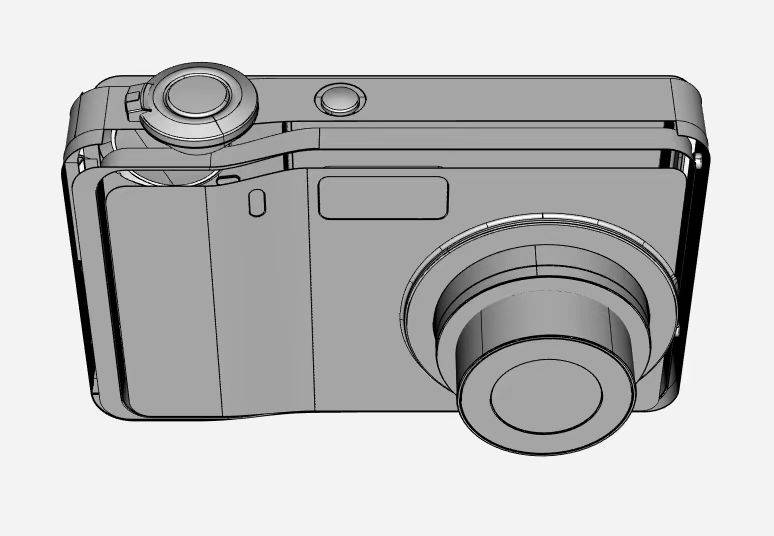

Digital & Lifestyle Camera Product Development

Project Scope

Digital camera and lifestyle camera development

Electronics, firmware, and mechanical design

Flash systems, storage, battery architecture

Tooling validation and mass production setup

Engineering Challenges

Designing a compact digital camera required balancing photo engineering performance with structural integrity while integrating sensor, optics, Xenon flash, battery, and storage into a constrained

Execution & Outcome

Through iterative optical tuning, internal layout optimization, and production-ready structural design, we delivered a stable, manufacturable camera platform optimized for image quality, durability, and mass production.

OEM Smart Glasses Development for Optical Retail

Project Scope

Smart glasses electronics integration

Frame material selection and structural design

Audio systems and wearable electronics

Manufacturing feasibility and assembly planning

Engineering Challenges

Developing smart glasses that remain lightweight, comfortable, and visually indistinguishable from standard optical frames while embedding audio, electronics, and battery systems.

Execution & Outcome

By engineering frame-first designs compatible with optical retail standards and integrating compact electronics without compromising comfort, we created lifestyle-ready smart glasses suitable for daily wear and prescription retail channels.

Heated Mug & Thermal Product OEM Manufacturing

Project Scope

Heated drinkware product development

Heating elements, battery systems, and MCU control

Waterproofing and safety considerations

Stainless steel and plastic component tooling

Engineering Challenges

Ensuring consistent temperature control, waterproof reliability, and safe battery integration within compact drinkware designs. Additional challenges included material compatibility and long-term durability under daily use.

Execution & Outcome

Delivered production-ready heated mug platforms with validated heating systems, stable firmware logic, and manufacturing processes suitable for retail distribution.

Manufacturing Systems & Quality Oversight

Discuss Your OEM Development Requirements